High Performance Cardan Shafts

Cardan shaft facilitate reliable torque transfer between spatially remote drive and output trains. Cardan shaft is a mechanical element used to transmit the torque or rotation in the devices that cannot be connected to each other directly. In order to transmit the torque to other device the shaft needs to be strong and must be able to bear the stress exerted on it.

NuhydroTM is pioneer in providing a comprehensive range of cardan shaft that satisfies the need of the client and industries. They are manufactured under the expert professional guidance and following the international standards to fit the mechanical devices all around the world. High quality products had helped us to be the biggest Cardan Shafts Manufacturers or Cardan shaft suppliers.

Function of Cardan Shafts

The overall function of a cardan shaft can be subdivided in 3 single functions:

- Torque and Speed

- Changing distance between power input and output

- Changing angle between power input and output

- All this is permanently elapsed by shocks resulting in vibrations and additional torsion forces

Features of Nuhydro Cardan Shafts

- Simplified Assembly

- Economical Maintenance

- High Quality

- Highest degree of strength and minimum distortion under load

- compact design

- High torque capacity-U.J. cross with low notch factor

- Dimensional Accuracy

- Perfect geometries by computer analysis

- Long Bearing Life

Industries in which it can be used

As an Industrial Cardan Shaft manufacturer or Universal Joint Shaft Suppliers, we cater to the paper mills, rolling mills, etc.

Certifications & Quality Assurances

We adhere all proper govt regulations, NuhydroTM produces the most durable and reliable cardan shafts with the use of latest technology based machines with the help of experienced workforce. With best quality standards, NuhydroTM is ISO-9001:2015 certified by TUV: SUD Germany for quality management.

Testing Procedures we do

- Spectro Analysis

- Harness Test

- Microstructure Analysis

- Dimensional Test

- Ultrasonic Test

- Magnetic Particle Test

- Die Penetration Test

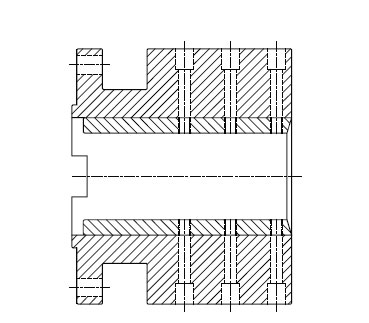

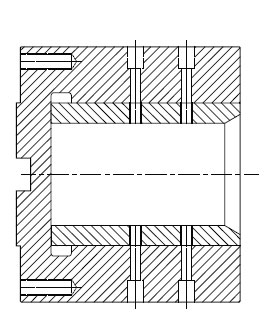

Excel for all the available series/Types of Industrial Cardan shafts we provide. Our range of Cardan Shafts can be categorized as follows

- Series X – Standard Cardan Shaft Series with bearing torque range of 786 to 28000 Nm

- Series S- Standard Cardan Shaft Series with bearing torque range of 500 to 8400 Nm

- Series W- Standard Cardan Shaft Series with bearing torque range of 4.55 to 80 kNm

- Series H- Standard Cardan Shaft Series with bearing torque range of 10.2 to 170 kNm

- Series E- Standard Cardan Shaft Series with bearing torque range of 28 to 1000 kNm

- Series F- Standard Cardan Shaft Series with bearing torque range of 1640 to 9000 kNm

- Series OT- Tunnel type Cardan Shaft Series with bearing torque range of 56 to 700 kNm

- Series IT- Tunnel type Cardan Shaft Series with bearing torque range of 50 to 560 kNm

In addition to the designs and sizes mentioned, a wide variety is available on request.

For More Details View Our Catalogue

Why Nuhydro

We firmly believes in providing the highest quality and the best product at the competitive prices to our customers. We are the most reliable High Performance Cardan Shafts Manufacturers in India & Universal Joint Shafts Manufacturers in India.

- Safe & reliable operation of all components

- Maximum life term of drive elements

- Excellent fitment with highest quality

- Fastest spare part delivery